The next generation of delta centrifugal temple tx systems emphasizes automation, safety, and sustainability. Producers are adding AI-fueled monitoring to predict maintenance needs before mechanical issues arise. Improved rotor dynamics minimize vibration and energy consumption, and closed chambers prevent contamination at high speeds. Touch operation and multilingual interfaces simplify ease of use. In processing biological samples or industrial fluids, the new delta centrifugal temple tx unites mechanical robustness with digital intelligence, setting the bar higher for precision, productivity, and durability in industrial and scientific applications.

The utilitarian uses of delta centrifugal temple tx have expanded due to technological advancements. It is utilized in pharmacology to ensure high-purity drug formulations. It is utilized in biotechnology for protein crystallization and vaccine synthesis. The extractive industry utilizes delta centrifugal temple tx to separate valuable minerals from raw mixture. In classrooms, it facilitates laboratory demonstrations of fluid flow. Even in the restoration of paintings, expert delta centrifugal temple tx facilitate cleaning and stabilizing delicate pigments. The applicability of delta centrifugal temple tx to so many different fields is evidence of its utility as an industrial and scientific agent for material separation.

{Keywords} of the future will unprecedentedly advance in performance and design. Future systems will feature adaptive balancing technology that adjusts to dynamic loads in real time. Intelligent rotors will track stress and fatigue in real time, allowing for extended service life. With IoT connectivity, multiple delta centrifugal temple tx units will be remotely managed to streamline laboratory networks. In biomedical applications, miniaturized devices will facilitate high-throughput screening with low sample volumes. These advancements are a step toward smarter, faster, and greener devices that revolutionize how separation processes are controlled in modern science.

Maintenance of delta centrifugal temple tx is essential to lab safety and data integrity. Cleaning should be performed immediately following every operation, with special attention to the elimination of any liquid spills or residues from samples. The rotor should always be handled gently, placed in an upright position during storage, and never subjected to shock. Periodic inspection of lid locks and gaskets ensures airtight operation. Power cord and fuse conditions should also be checked by operators. Annual servicing by skilled technicians adds lifespan. Through regular care processes, delta centrifugal temple tx safely and accurately continues to operate.

The delta centrifugal temple tx is an essential instrument in science and engineering. It is able to separate material constituents based on their differences in density by rotating them at very high speeds. In biotechnology, it is used to purify cells, DNA, and enzymes. In chemistry, it purifies liquids and removes impurities from them. delta centrifugal temple tx also play a crucial role in medical diagnosis when preparing blood samples. Their mechanical precision and regulation of speed ensure safe use. Constantly enhanced design and electronic monitoring system development enhances efficiency, and delta centrifugal temple tx are thus inevitable in numerous modern applications.

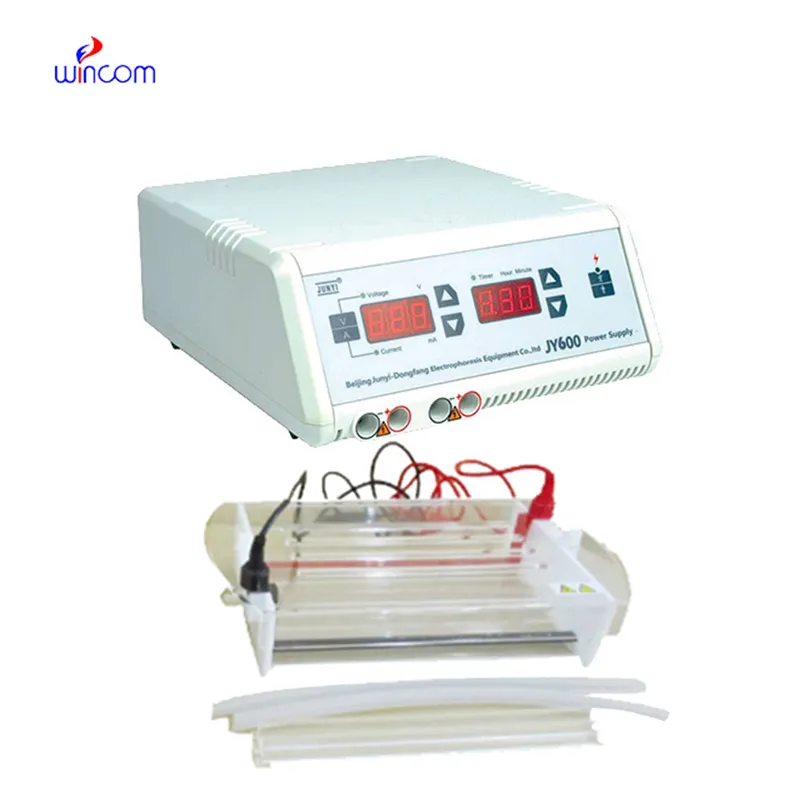

Q: What are the main components of a centrifuge? A: Key components include the rotor, motor, control panel, safety lid, and chamber, each working together to achieve precise separation. Q: How can I verify that a centrifuge is functioning correctly? A: Check that the machine runs smoothly without any unusual vibrations or noises, check the speed accuracy and evaluate the results to ensure consistent separation. Q: Is it safe to open a centrifuge immediately after use? A: No, the device should come to a complete stop before opening to avoid injury or sample disruption. Q: How should a centrifuge be stored when not in use? A:Store it unplugged, covered, and in a dry, dust-free environment to protect internal components from moisture and corrosion. Q: Can centrifuge operation be automated? A: Yes, modern models include programmable controls and digital interfaces that allow automated speed, time, and temperature settings.

We’ve been using this mri machine for several months, and the image clarity is excellent. It’s reliable and easy for our team to operate.

The delivery bed is well-designed and reliable. Our staff finds it simple to operate, and patients feel comfortable using it.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Hello, I’m interested in your centrifuge models for laboratory use. Could you please send me more ...

I’d like to inquire about your x-ray machine models. Could you provide the technical datasheet, wa...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China